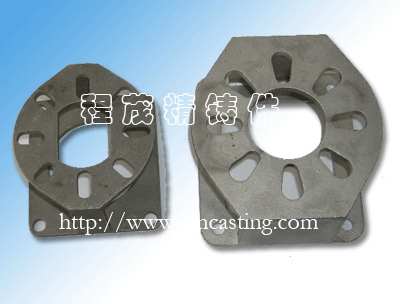

Dewaxing casting is also called precision casting, and its products have higher precision. It can be directly used for the shape of parts without processing or very little processing. It is an advanced technology for near net shaping.

1. Spray rust removal:

The compressed air of the compressor is treated by oil-water separation, and the abrasive is ejected from the nozzle at high speed. The pressure of the compressed air is generally 4-0.6MPa. Precision casting uses high-speed mushrooms to contact alloy steel castings to generate frictional impact, remove oxide scale and corrosion.

2. Projectile rust removal:

The impeller blades of the high-speed rotating granulator are rotated to disperse the abrasives on the surface of the cast steel, so that the abrasives rotate at a high speed on the surface of the cast steel. Oxide. This method has good effect and good rust removal effect. A certain degree of roughness can be obtained on the cast steel surface, which is conducive to coating adhesion, low labor intensity, and environmental protection. Manufacturers should give priority to this method.

This method does not require positioning. High efficiency. No dead ends are left in the nozzle. The high-quality weighing gives the alloy cast steel surface a certain roughness, which is conducive to the adhesion of the coating layer.

Related News

- Precision casting mirror treatment and dewaxing casting

- Controlling the high quality of precision cast steel is the key

- Production Development of Guangdong Stainless Steel Casting Alloy Steel

- Characteristics of precision cast steel investment casting

- Dongguan precision casting kitchen hardware pendant varieties

- Processing steps and cleaning methods of Guangdong stainless steel castings

- Definition of Guangdong carbon steel casting

- Classification of Dongguan Precision Casting Special Casting

- Dongguan Precision Casting Factory

- What are the types of alloy steel casting hardware in Guangdong

- Some properties of dewaxing casting of stainless steel castings

- How to achieve precise temperature control in precision casting

- How to ensure that stainless steel precision castings meet standards

- What are the formulas for cleaning the surface of stainless steel castings?

- What determines the performance of precision casting castings

- How to deal with the deformation in the production of precision cast steel