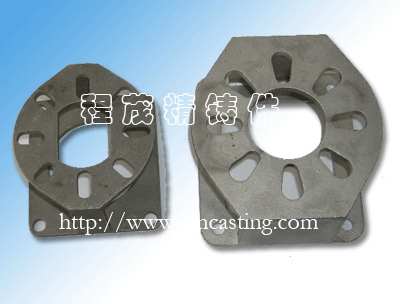

Equipment hardware

Guangdong carbon steel casting, Refers to the general term for the process of obtaining precise size castings. Compared with the traditional sand casting process, the casting size obtained by precision casting is more accurate and the surface finish is better. It includes: investment casting, ceramic mold casting, metal mold casting, pressure casting, and lost foam casting.

Precision casting is also called lost wax casting. Its products are precise, complex, and close to the final shape of the part. It can be used directly without processing or with little processing. Therefore, investment casting is an advanced technology with near net shape.

It includes: investment casting, ceramic mold casting, metal mold casting, pressure casting, and lost foam casting.

One of the more commonly used is investment casting, also known asLost wax casting: Use appropriate investment materials (such as paraffin) to make investment molds; repeat the steps of dipping refractory paint and sprinkling refractory sand on the investment mold to harden the shell and dry; then melt the internal investment mold to obtain a cavity; baking type Shell to obtain sufficient strength, and burn off the remaining investment materials; cast the required metal materials; solidify and cool, clean the sand after shelling, so as to obtain high-precision finished products. According to product needs or heat treatment, cold processing and surface treatment.

Since investment casting was used in industrial production in the 1940s, it has been developing at a relatively rapid rate for half a century. Especially European and American countries are developing rapidly. Investment casting is used in the aviation and weapons sectors, and is used in almost all industrial sectors, especially in electronics, petroleum, chemical, energy, transportation, light industry, textiles, pharmaceuticals, medical equipment, pumps and valves. my country has also developed rapidly in recent years.

Guangdong Stainless Steel CastingTechnological development enables investment casting not only to produce small castings, but also to produce larger castings. The outline size of the largest investment casting is nearly 2m, while the minimum wall thickness is less than 2mm. At the same time, investment castings are becoming more precise. In addition to linear tolerances, parts can also achieve higher geometric tolerances. The surface roughness of investment castings is getting smaller and smaller, which can reach Ra0.4μm.